-

Technic Explorer

-

Technische Publikationen

- TI Nr. 1 - Werkseitige Oberflächenausrüstungen von elastischen Bodenbelägen

- TI Nr. 2 - Einfluss von Stuhl- und Möbelgleitern sowie Stuhl- und Möbelrollen

- TI Nr. 3 - Einsatz von elastischen Bodenbelägen in hygienerelevanten Bereichen – Räder und Rollsysteme

- TI Nr. 4 - Sauberlaufzonen: Unfallgefahren mindern und Unterhaltskosten reduzieren

- TI No. 4 - Clean-off zones: Reduce the risk of accidents and decrease maintenance costs

- TI Nr. 5 - Treppensysteme: Leitfaden zur sach- und fachgerechten Sanierung und Belegung

- Tl Nr. 6 - Vertikale Verwendung von elastischen Bodenbelägen

- TI Nr. 7 – Elastische Bodenbeläge auf temperierten Untergründen

- BI Nr. 1 - Reinigung und Pflege

-

FRT-Leitfaden

-

Weitere Dokumente

TI No. 4 – Clean-off zones: Reduce the risk of accidents and decrease maintenance costs

Introduction:

Thanks to their rich variety of design possibilities, floor coverings play an important part in establishing a building’s character. However, unlike the other surfaces in a room (walls and ceiling), they are subject to numerous loads and must therefore meet high requirements in accordance with their load class.

Particularly in entrance areas, floor coverings are exposed to especially heavy loads, which can have a negative impact on appearance and functionality even after a short period of use.

Floor coverings can be sustainably protected by careful and usage-oriented planning. High-quality entrance matting systems are ideally suited for this purpose: they reliably absorb dirt particles and moisture and thus minimise the risk of their being walked further into the building. In this way, the entrance matting system not

only ensures that the floor coverings retain their value, but also effectively prevents slipping accidents and demonstrably reduces cleaning time and costs.

Furthermore, the variety of available designs means that modern entrance matting systems can be easily integrated into any architectural concept. A broad colour spectrum allows the

creation of both harmonious and high-contrast combinations with the interior design and surroundings. This means that entrance matting systems can be used not only to reduce dirt, but also as a prestigious design element in architectural interior design. Every building design should include a high-quality entrance matting system, therefore.

Definition: What is dirt?

“Dirt is matter (often in the form of small particles, traces, discolorations) that, in the view of the user or observer, is unwelcome in the place in which it is found, in particular dust and sticky, earthy, greasy or fatty residues on surfaces

(which can collect more dust in their turn).”

[German-language Wikipedia, accessed on

18/02/2020]

Conclusion: “Dirt is matter in the wrong place.”

[Martin Lutz, FIGR Forschungs- and Prüfinstitut

für Facility Management GmbH]

What types of dirt are found in entrance areas?

a. Wet and dry road grime

– Coarse dirt (sand, small stones)

– Fine dust

– Moisture

b. Winter grime

– Gritting material (salt, grit)

– Snow

c. Special areas (workshops, catering

facilities, etc.)

– Oils

– Fats

How does dirt spread around a building?

Dirt can spread around a building in different ways. A large part of the dirt first enters the building through the entrances – with side

entrances also playing a significant role. It can then be spread through transfer from footwear,

draughts, and ventilation and air-conditioning systems, but also through unsuitable cleaning procedures (e.g. exclusively wet wiping

without prior removal of any loose fine dirt).

What effects does dirt have on floor coverings?

Dirt alters the product’s properties:

- Abrasive effect of particles (e.g. mineral dusts, fine sand) leads to scratches and surface wear, as well as to dirt accumulation in floor-covering surfaces

- Deterioration of appearance

- Increased risk of slipping

How is the value retention of floor coverings increased by using a barrier matting system?

a. Reduction in dirt entering

Various scientific studies show that the use of clean-off zones increases the service life of floor coverings in buildings. Soiling and wear of floor coverings are significantly reduced.

As part of a master’s thesis at the Berlin University of Applied Sciences (HTW Berlin), comparative studies were carried out on the effects of entrance matting systems on protection against dirt [I]. Comparisons were made of real soiling scenarios with and without a clean-off zone, and laboratory tests were run with artificial, reproducible soiling. The 3-zone entrance matting system examined here was 5.40 m long and consisted in equal parts of brushes in the first zone, a ribbed carpet insert in the second zone and a polyamide insert (textile entrance matting system) in the third zone. Different types of dirt, both dry and wet, were walked into the test setup with treaded soles in different thicknesses, and the dirt absorption of the clean-off zone was determined gravimetrically. It was found that, in this simulated entrance area,

an average of 86% of the dirt walked in was taken up by the 3-zone entrance matting system. The Deutsches Teppich-Forschungsinstitut (German carpet research institute) carried out a

practical test to compare the soiling behaviour of two carpets laid with and without a clean-off zone. The beneficial effect of the clean-off zone could be quantified and proven by measuring the

dirt walked in and the resulting visible soiling. The quantity of dirt walked in was reduced by 50–70% [II]. The British institution Cleaning Research International conducted a study in a hospital

entrance area that proved the effectiveness of a 3-m-long clean-off zone [III]. The dirt brought into the building was reduced on average by 95.1%. See also: Bachelor thesis at the Hochschule

Niederrhein, University of Applied Sciences, on the effectiveness of different types of dirt-collection mats in terms of dirt and water absorption [IV].

How is the value retention of floor coverings increased by using a barrier matting system?

b. Slip resistance

The German Institution for Statutory Accident Insurance and Prevention in the Health and Welfare Services (BGW – Berufsgenossenschaft für Gesundheitsdienst und Wohlfahrtspflege) reports: “Most accidents happen on the ground,

however: literally on the floor. These are tripping, slipping and falling accidents, many of which occur due to smooth, slippery and dirty floor coverings or tripping hazards.” As a result, the BGW expressly recommends clean-off zones in entrance areas [V].

(https://dguv.de/de/index.jsp)

The DGUV (Deutsche Gesetzliche Unfallversicherung – German Statutory Accident Insurance) Rule 108-003 states: “In entrance

areas, the aim must be to transfer as little moisture and dirt as possible to the adjacent traffic routes after passing through. For this reason, large-area dirt and moisture collectors must be

installed in areas that are entered directly from outside through entrances and into which moisture can enter and/or be walked in from outside. The construction and surface area of this provision

depends, among other things, on the number of people who regularly pass through the entrances. It is recommended that dirt and moisture collectors be arranged so as to extend over the entire passage width.

The dirt and moisture collectors […] must be arranged in such a way that they cannot slip and do not constitute a tripping hazard.” (https://publikationen.dguv.de/dguv/pdf/10002/108-003.pdf)

General traffic safety obligation (BGB § 823):

“In the context of the general traffic safety obligation, every owner of a building or business must ensure that there is no danger of accidents to public (customer/visitor) traffic in his or her

premises.” (e.g.: https://www.gesetze-im internet.de/bgb/_823.html)

How is the ideal 3-zone entrance matting system structured?

How is the ideal 3-zone entrance matting system structured?

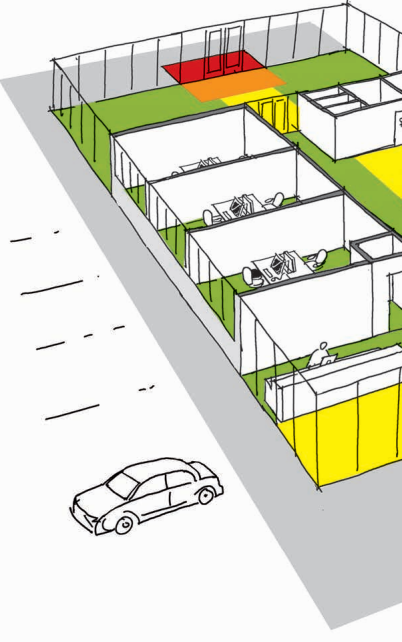

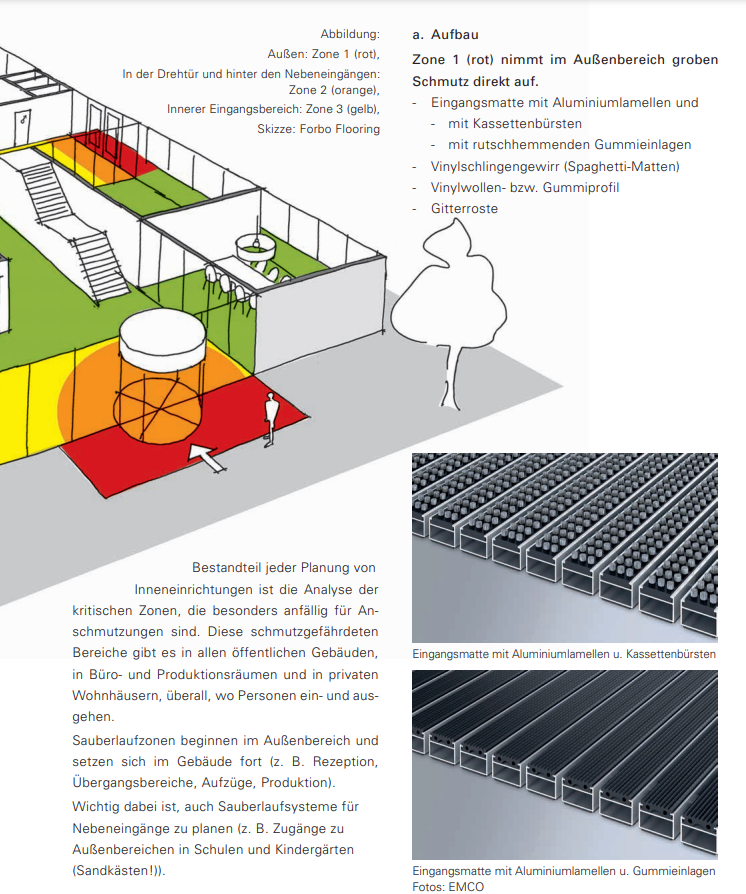

a. Structure

Zone 2 (orange) absorbs fine dirt and moisture

indoors and outdoors (revolving door).

- Textile entrance matting systems (suitable for commercial use)

- Aluminium grid with textile inserts with good scratching properties

Zone 3 (yellow) absorbs residual moisture

and fine dirt.

- Textile entrance matting systems (suitable for commercial use)

- Aluminium grid with textile inserts

b. Requirements

- Adequate dimensions (4.5–6 m / ideal: 8–10 steps)

- No possibility of avoiding it

- Good dirt and moisture retention

- High wear resistance

- High slip resistance

- No tripping hazards (no raised edges)

- Easy to clean

- Long technical service life

- Weather resistance of products suitable for outdoor use

- Good appearance

- Adaptation to the building conditions

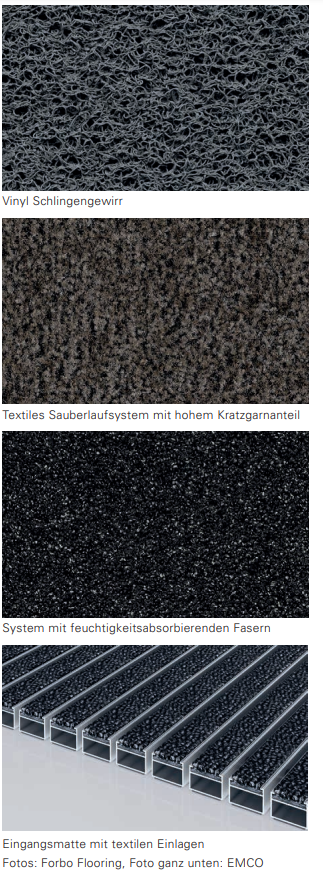

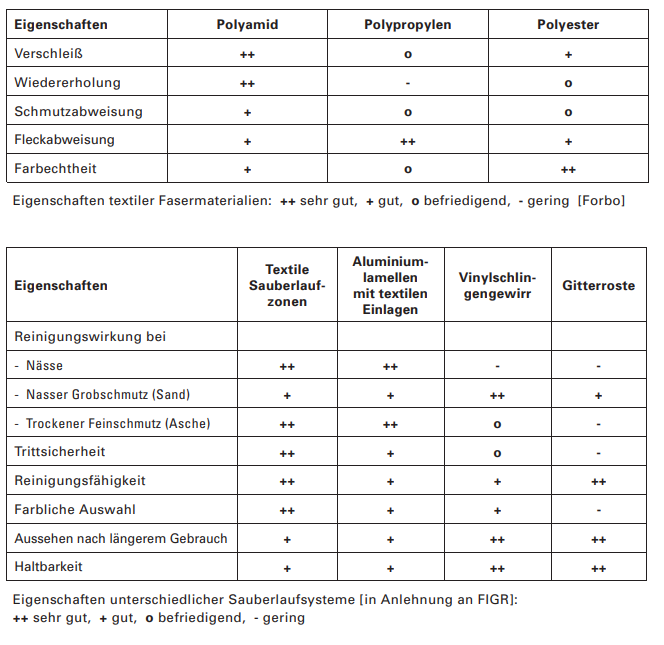

c. Textile fibre materials

See table at top of right-hand page

d. Freedom in design

Modern entrance matting systems are a design element and a visible contribution to the architecture. Products for the dirt-collection zone are available in a multitude of colours and designs,

fully suited to use in commercial buildings and with the fire rating Cfl-s1 or Bfl-s1. Both classes correspond to German class B1 according to DIN 4102-1, „schwerentflammbar“.

And, if that is not enough, you can create your own bespoke entrance matting system.

Innovative technology makes it possible to print your own logos, intense colours, special shapes and design variants – completely personalised.

How is a clean-off zone maintained?

According to the frequency of use and the amount of dirt that enters, clean-off zones should be cleaned of loose dirt at least daily by

vacuuming (preferably with a brush vacuum cleaner). Depending on the weather, the clean-off zone may be wet at the time of cleaning. Special wet-dry vacuum cleaners with dual filtration are

suitable for this purpose and can be used simultaneously for both dry dirt and moisture.

Deep cleaning should be carried out as required, taking into account the design and material of your entrance matting system.

The manufacturer’s cleaning instructions must be observed.

Conclusion

Well thought-out entrance matting systems reliably absorb most of the dirt and moisture before it is walked into the building and therefore offer optimum protection for all entrance areas. Floor coverings are greatly protected against dirt and wear

Entrance matting systems reduce the risk of slipping accidents, which usually occur due to dirt and moisture on floor coverings – for this reason, the BGW expressly recommends the use of clean-off zones in entrance areas.

The length of the entrance matting system makes a significant contribution to reducing the amount of dirt that is walked in. Ideally, the entrance matting

system should extend over a walking depth of 8–10 steps, starting outside the building and continuing inside.

Modern entrance matting systems make a visible contribution to the architecture, because they can be tailored individually and exactly to the design requirements of the respective building

and user.

When planning or modernising a building, it is essential to make allowance for issues of floor-covering safety, value retention and cleaning costs by using a high-quality entrance matting

system.

Disclaimer

This technical information has been prepared with great care. All information and notes correspond to our knowledge at the time of

printing.

However, no responsibility can be taken for correctness or completeness in individual cases. We reserve the right to make changes due to technical developments.

Publisher

FEB – Fachverband der Hersteller elastischer Bodenbeläge e. V. (German association of flooring manufacturers)

www.feb-ev.com, info@feb-ev.com

Created by the technology working group in FEB e.V. in cooperation with the following associations and institutes:

- EPLF – European Producers of Laminate Flooring

- MMFA – Multilayer Modular Flooring Association

- FIGR – Forschungs- and Prüfinstitut für [research and test institute for] Facility Management GmbH

- TFI – Textile and Flooring Institute at RWTH Aachen University

- Working group CC/I Nilfisk GmbH

Copyright

© FEB July 2019 / February 2020

Any part of this document may be reprinted, copied or transmitted with electronic systems provided the

source is indicated.

References

I Albert, J. Weber, M.: Vergleichende Untersuchungen zu den Auswirkungen von entrance matting systems auf the Schmutzabwehr

in Immobilien unter anwendungstechnischen Bedingungen; Masterabeit, Hochschule für Technik and Wirtschaft Berlin, 10/2017

II Klingenberger, H., Dünnwald, F.D.: Welche Wirkung hat eine textile Schmutzfangzone auf einen verlegten Teppichboden? OBJEKT

12/84, S. 81-84

III N. N.: Study into the Effectiveness of Coral Entrance Matting, Cleaning Research International, 2016

IV Brada, I.: Vergleichende Untersuchungen von industriell aufbereitbaren im neuen and aufbereiteten Zustand and nicht aufbereitbaren

Schmutzfangmatten unter anwendungstechnischen Bedingungen. Bachelorarbeit, Hochschule Niederrhein, SS 2015

V BGW – News (Ausgabe vom 10.06.2009)